A posição da válvula é um daqueles pequenos sinais que silenciosamente geram grandes consequências. Uma pequena variação de alguns graus em uma válvula de medição de distrito, uma comporta de irrigação deixada semiaberta, uma válvula girada muitas vezes durante um turno da noite... e de repente você tem reclamações de pressão, suspeita de vazamento ou uma longa viagem para uma verificação manual.

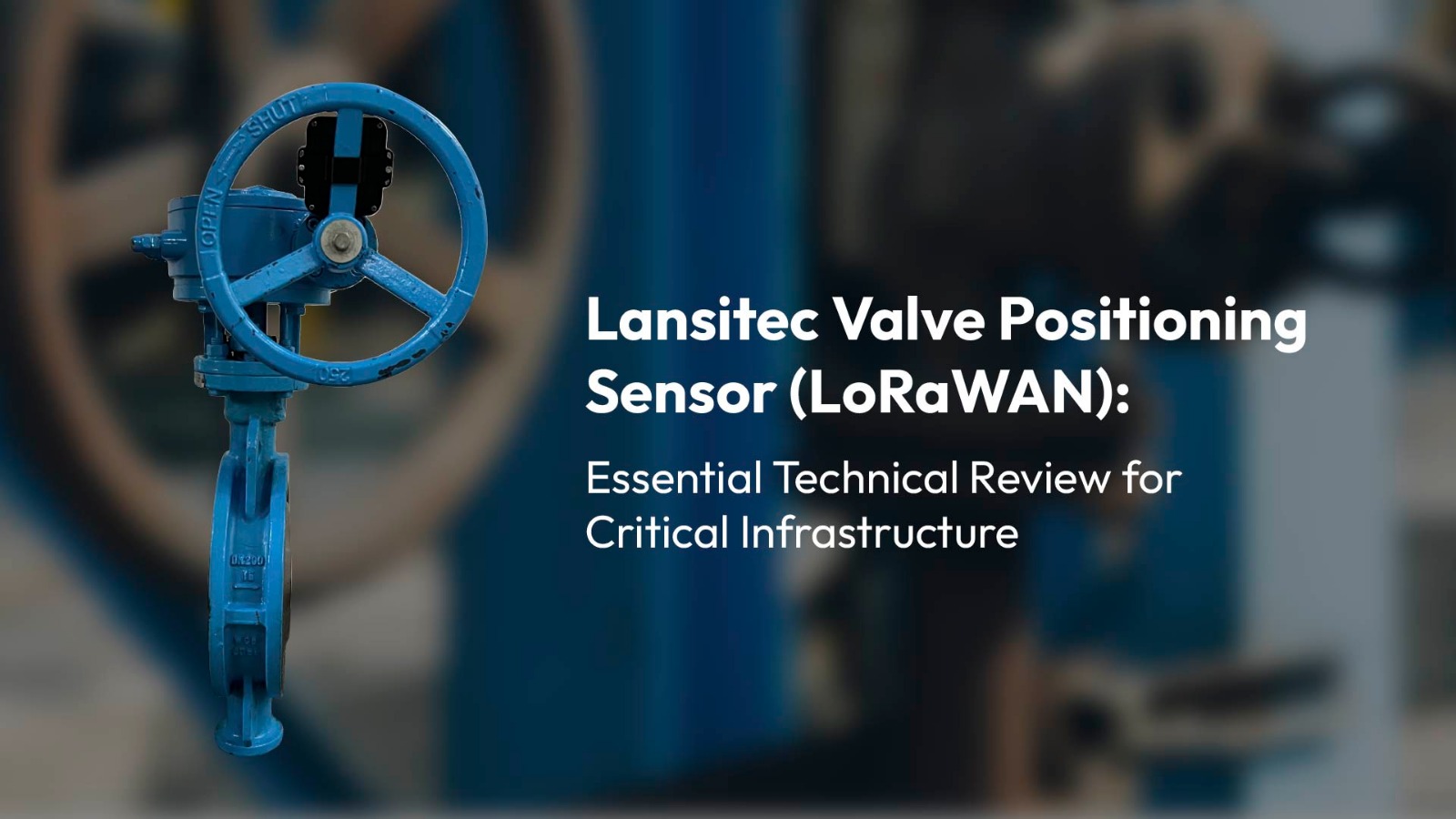

da Lansitec Sensor de posicionamento de válvula Vai direto ao ponto. Ele mede o ângulo de rotação com precisão de 1°, detecta a direção (para frente ou para trás), conta o número total de voltas e envia relatórios para o seu dispositivo. LoRaWAN gateway em tempo quase real.

Que problemas um sensor de posicionamento de válvula realmente resolve?

Em nossa experiência, projetos de monitoramento de válvulas frequentemente falham por motivos banais: baterias descarregam, invólucros falham, instaladores detestam a montagem ou os dados chegam tarde demais para que se possa tomar alguma providência. Este sensor foi projetado para reduzir esses "custos operacionais":

- Elimina pontos cegosVocê obtém a posição verificada da válvula e o histórico de giro, não apenas "alguém diz que está aberta".“

- Cortes de rolos de caminhãoA visibilidade remota significa menos verificações presenciais, especialmente para redes distribuídas.

- Melhora a responsabilizaçãoA contagem de turnos e a direção das viradas ajudam a identificar intervenções incomuns ou procedimentos incorretos.

- Manutenção preditivaMonitore os padrões de uso das válvulas para programar a manutenção antes que ocorram falhas. O acelerômetro 3D adiciona detecção de anomalias baseada em movimento para identificação precoce de falhas.

- Atualizações de firmware sem tempo de inatividade: A tecnologia FOTA (Firmware Over-The-Air) via Bluetooth permite atualizações remotas sem a necessidade de remover os sensores, o que é essencial para instalações em barragens hidrelétricas, estações de bombeamento remotas ou serviços públicos subterrâneos.

Especificações essenciais que importam no campo

Eis a lista resumida que consideramos ao decidir se um sensor de válvula é realmente viável para implantação em larga escala:

- Medição de ângulo: 0° a 360°, precisão de 1°, ±50 voltas no máximo, atraso de 5 segundos no relatório

- RobustezGrau de proteção IP68, peso de 133 g, caixa em PC + ABS, temperatura de operação de -20 °C a +70 °C, umidade relativa de 0 a 951 TP3T.

- Duração da bateria: 2×2800 mAh (5600 mAh no total), com duração estimada de ~4 anos considerando 5 relatórios de estado da válvula por dia

- LoRaWAN rádioSuporte multibanda (variantes EU868, US915, AS923 e outras), AES-128, sensibilidade de -137 dBm a SF12 / 125 kHz e alcance de comunicação urbana superior a 1 km.

Como funciona o sensor de posicionamento da válvula no LoRaWAN

O sensor utiliza um sensor magnético integrado para medir a rotação e a direção da válvula, enviando então atualizações através de um dispositivo. LoRaWAN para o seu gateway e servidor de rede.

Em relação à entrada na rede e segurança: suporta ativação OTAA ou ABP, o que corresponde LoRaWAN requisitos de integração de dispositivos no Especificação da LoRa Alliance.

Também utiliza criptografia AES-128, em consonância com a forma como LoRaWAN Protege cargas úteis e chaves de sessão.

Considerações sobre manutenção e operações de frota

É aqui que o dispositivo se mostra "construído para projetos reais", e não para demonstrações.

Atualizações de firmware via Bluetooth FOTA

As atualizações de firmware são suportadas via Bluetooth, permitindo que você atualize sem precisar remover a unidade da válvula.

Para grandes implantações municipais ou industriais, isso importa mais do que as equipes imaginam. Mudanças de firmware acontecem. Mudanças de política acontecem. Você não quer uma escada e uma chave inglesa para cada atualização.

Sensores adicionais para instalação e confiabilidade.

O acelerômetro 3D incluído (sensor G) oferece suporte à detecção baseada em movimento e auxílio na calibração.

Isso pode ser útil para confirmar eventos de manuseio ou refinar o alinhamento da instalação na fase de comissionamento.

Sincronização de rede, controle de carga útil e eficiência de tempo de transmissão

A especificação também lista suporte a TDMA, sincronização de relógio/sincronização de relatórios, além de recursos de compressão de dados Bluetooth e filtragem de payload. Se você estiver executando implantações densas ou orçamentos de tempo de transmissão limitados, esses recursos podem ajudar a manter os relatórios organizados.

Casos de uso mais adequados para monitoramento da posição da válvula

A Lansitec posiciona o produto exatamente para ambientes onde as válvulas estão por toda parte e os humanos não:

- Distribuição municipal de águaMonitorar os ângulos e a utilização das válvulas para auxiliar na manutenção preventiva e reduzir o desperdício de água ou alterações não autorizadas.

- Irrigação inteligenteMonitorar válvulas de irrigação em fazendas ou campos de golfe para garantir a irrigação adequada e a detecção precoce de problemas.

- Infraestrutura remotaBarragens, estações de bombeamento remotas e locais de válvulas de difícil acesso, onde decisões rápidas dependem do estado da situação em locais remotos.

Se você estiver mirando na Europa (EU868), América do Norte (US915) ou em muitos planos da região Ásia-Pacífico (variantes AS923), a lista de bandas regionais suportadas é ampla o suficiente para cobrir as necessidades típicas. LoRaWAN implantações.

Prós e contras: uma avaliação prática

| Prós | Contras (o que validar) |

| A resolução de ângulo de 1° combinada com a contagem de voltas fornece dados operacionais acionáveis, e não apenas "aberto/fechado". | O limite de rotação (±50) é adequado para a maioria das operações de válvulas, mas confirme se ele corresponde ao tipo de válvula e aos procedimentos de manutenção. |

| A classificação IP68 e a bateria com duração de vários anos permitem implantações de nível de concessionária com manutenção mínima. | “O termo ”IP68” ainda precisa de uma definição em seu processo de aquisição: a profundidade e a duração da imersão são específicas para cada aplicação, de acordo com a norma IEC 60529, portanto, alinhe as expectativas nas especificações do projeto. |

| O Bluetooth FOTA é um recurso prático que reduz os custos de serviço a longo prazo. |

O Sensor de posicionamento de válvula Lansitec Aborda o desafio fundamental do monitoramento de infraestrutura de válvulas distribuídas. Sua combinação de precisão de 1°, duração da bateria de 4 anos e LoRaWAN A conectividade fornece dados acionáveis sem a sobrecarga operacional de inspeções manuais, tornando-se uma solução prática para concessionárias de água, operações agrícolas e instalações industriais que gerenciam redes de válvulas críticas.