How LoRaWAN Sensors Keep Crews Cool, Productive, and OSHA-Ready

The hottest June on record rolled straight into July last year; forecasters expect a repeat in 2025. For employers, that means more than sweaty crews—it means new legal exposure. OSHA’s forthcoming Heat Injury & Illness Prevention Standard (§1910.1023), the EU Framework Directive 89/391/EEC, and ISO 45001 audits all demand that companies document ambient heat, track individual exposure, and react fast when limits are breached. The good news: you can meet those obligations with just three purpose-built devices from the lansitec catalogue.

When the mercury climbs, so does the regulatory pressure. Across the U.S., the forthcoming OSHA Heat Injury & Illness Prevention Standard intersects with long-standing EU directives and ISO 45001 audits, demanding verifiable, continuous proof that employers measure ambient heat, track individual exposure, and react in real time.

Below is a field-tested blueprint—built entirely on Lansitec LoRaWAN® sensors and an IP67 gateway—that lets EHS teams tick every box without burying IT in cables or SIM cards.

Why Heat-Stress Compliance Matters in 2025

- More frequent heat waves: 2024 tied the global record for hottest year; forecasters expect another brutal season.

- New legal teeth: OSHA’s draft §1910.1023 cites mandatory monitoring of WBGT (wet-bulb globe temperature) and timed rest breaks; EU Framework Directive 89/391/EEC imposes similar “state-of-the-art” duty of care.

- Insurance premiums & litigation: Failure to document heat-risk controls drives up workers-comp costs and lawsuits.

The Three-Piece IoT Toolkit for Real-Time Heat Safety

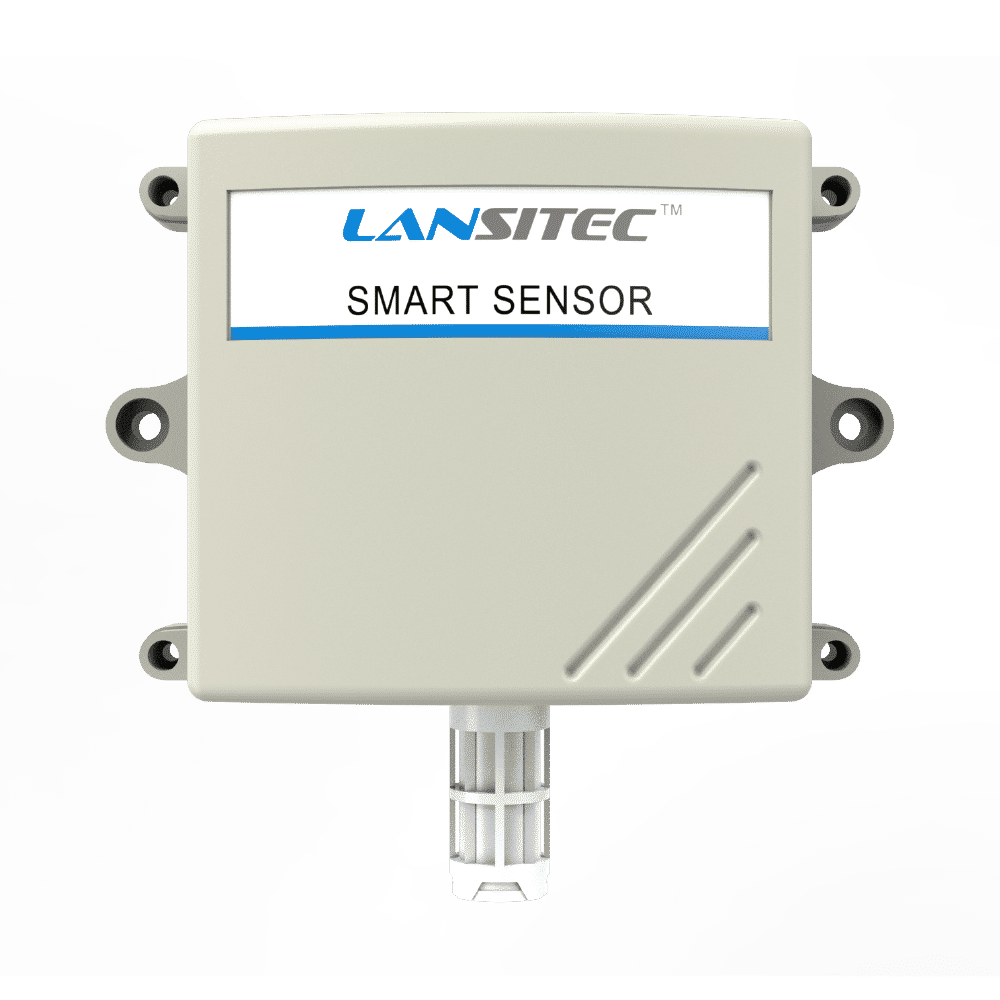

LoRaWAN Temperature & Humidity Sensor – Ambient Risk Baseline

- Spec highlights: –40 °C … +125 °C (±0.3 °C), 0 – 99 % RH (±3 %), IP65, 19 000 mAh battery → ≈ 5 years life.

- Compliance punch: 15-minute logs feed WBGT formulas, proving that break schedules are grounded in objective data.

- Install tip: Mag-mount one “puck” on every 25 m radius to capture micro-climate hotspots.

A LoRaWAN Temperature & Humidity Sensor is the first building block. Its industrial ABS housing (IP65) shields electronics that read –40 °C … +125 °C (±0.3 °C) and 0 … 99 % RH (±3 %) while a 19000 mAh lithium thionyl-chloride cell keeps it alive for roughly five years, even when it transmits every 15 minutes. By scattering a handful of these “pucks” around a job site, you create the objective data stream regulators expect when they ask, “How did you decide it was time for a break?”

Helmet Sensor – Personal Exposure & Safety Alerts

- Spec highlights: LoRaWAN 1.0.2B, Bluetooth 5.0, GNSS (<2.5 m), IP66 / IK10, fall- & panic-alarm, barometer (±1 m).

- Compliance punch: Links ambient heat to who was in it and how long; auto-verifies helmet wear and pushes haptic alerts if exposure limits near the OSHA TLV.

- Extra credit: BLE relay lets the sensor pick up tagged tools, so a dropped hammer doesn’t become a head-injury hazard.

Next, clip on the LoRaWAN Helmet Sensor. The palm-sized module combines GNSS (< 2.5 m accuracy), Bluetooth 5.0, a 3-axis accelerometer, barometer, and two tactile buttons inside an IP66/IK10 shell. Every few seconds, it stamps the wearer’s position, motion state, and battery level into a LoRaWAN uplink. When ambient WBGT crosses a threshold, the cloud vibrates the helmet and starts a personal “heat clock,” automatically proving that nobody stayed in the danger zone longer than OSHA’s time-weighted limits. The same sensor raises an instant alarm if it senses a fall, a sudden altitude drop, or a panic-button press.

Outdoor LoRaWAN Gateway – Rugged Site Back-Haul

- Spec highlights: 8/16 SX1301 channels, PoE power, LTE Cat 4 & Wi-Fi back-haul, IP67, –30 … +55 °C, 12 W typical draw .

- Compliance punch: One pole-mount unit covers > 500 nodes over several hectares—ideal for pop-up jobsites where trenching fiber isn’t in scope.

Both devices speak native LoRaWAN, so a single Outdoor LoRaWAN Gateway can blanket a multi-hectare work zone. Housed in an aluminium IP67 enclosure, the gateway integrates up to two SX1301 concentrators (8 or 16 channels), PoE power, LTE Cat 4 and Wi-Fi back-haul while surviving –30 °C to +55 °C and drawing only ~12 W . Mount it six metres up a lighting pole, plug in Ethernet-over-PoE and your private IoT network is live—no trenching, no SIM cards in every node.

Use-Case Walk-Through: Keeping a Construction Crew Safe at 34 °C WBGT

| Phase | On-Site Action | Sensor & Gateway Flow | Compliance Win |

|---|---|---|---|

| 1 . Dawn check-in | Workers badge in; helmets self-report battery OK + wear status. | Helmet → LoRa → Gateway → Cloud | Digital PPE log satisfies OSHA 29 CFR 1926.100. |

| 2 . Shift monitoring | Ambient pucks push 15-min readings; cloud computes WBGT. | TH Sensor → Gateway | Auto-alerts when WBGT > 26 °C start hydration/rest cycle. |

| 3 . Dynamic zoning | Zone hits 32 °C; cloud vibrates helmets inside zone and starts “heat clock”. | Cloud → SMS / Teams | Proves no one exceeds 20 min/hr in high-heat per NIOSH TLV. |

| 4 . Incident response | Helmet detects fall + panic button; last 5 min vitals uploaded. | Helmet → Gateway → Cloud | One-click PDF supports ISO 45001 investigation. |

| 5 . Day-end audit | Auto-report exports °C/RH curve, individual exposure, breaks. | Cloud BI dashboard | Six-year record retention for inspectors & insurers. |

Regulatory Checklist—How the Stack Scores

- Continuous ambient logging ✔ “State-of-the-art” sensors meet EU 89/391/EEC Article 5 duty.

- Individual exposure time-stamps ✔ Helmet GNSS/BLE trails fulfill OSHA draft §1910.1023(c)(1).

- PPE verification ✔ Wear-detection proves hard-hat compliance under 29 CFR 1926 Subpart E.

- Incident documentation ✔ 10-sec barometer & accelerometer buffer supports OSHA form 301 reporting.

- Data retention ✔ Cloud archive with AES-128 encrypt matches ISO 45001 Clause 7.5.

Deployment Tips for HSE & IT Teams

- Site survey first: Mount the gateway mid-site at ≥6 m height for optimal LoRa RSSI.

- Sensor hard-limits: Set the TH-sensor uplink to 900 s in low-risk zones, 300 s in high-risk zones.

- Battery discipline: Replace helmet-sensor magnetic chargers at the tool crib; a 15-min top-up covers an 8-hr shift.

- Dashboard KPIs: Track Max WBGT, Longest individual exposure, and % of time in rest mode.

- Training module: A one-slide toolbox talk explaining helmet vibration alerts cuts false panic calls by 40 %.

Perform a quick RF survey and place the gateway roughly center-site at eye-level with nearby rooftops; LoRa should reach every corner. Configure the ambient sensor to 15-minute reports in low-risk areas and 5-minute bursts near hot machinery. A 15-minute charge at the tool crib gives the helmet enough juice for an eight-hour shift, and a one-slide toolbox talk explaining vibration alerts typically halves false panic calls.

Conclusion: Data-Driven Cooling Pays for Itself

With one IP67 gateway, a ring of temperature-and-humidity pucks, and smart helmets that double as personal alerting devices, safety managers gain live situational awareness plus airtight compliance evidence all before the dog days of 2025 arrive. The hardware is rugged enough for redeployment, the battery life outlasts the project, and the data granularity turns regulatory headaches into a routine dashboard check.

Implement now, and when the next summer scorcher hits, you’ll have workers hydrated, auditors satisfied, and downtime melting away.

Ready to pilot? Contact us for demo access and a battery-budget worksheet that sizes the solution for your specific crew and climate.