A tier-1 third-party logistics (3PL) provider cut annual pallet-loss write-offs by 86 % and trimmed forklift mileage by 27 % after equipping every pallet with Lansitec Bluetooth beacons that cooperate as a self-healing mesh. Exterior “leader” beacons forward the IDs of interior beacons to SocketSync Gateway and Macro Bluetooth Gateways, which backhaul compressed payloads over LoRaWAN. The battery-powered system needed no Ethernet runs and no mains rewiring, reaching pay-back in seven weeks.

Customer Profile and Challenge in Pallet Tracking

The customer operates a 40000 m² ambient warehouse, turning ≈ 8000 pallets per day. Stacks four-high and shrink-wrap with metallised film regularly blocked direct BLE signals, so single-tag solutions left blind spots; misplaced pallets cost > €28k yearly in write-offs and man-hours.

Lansitec Solution for Pallet Tracking Visibility

| Layer | Recommended device(s) | Why it fits pallet‐tracking & Bluetooth-mesh |

| Beacon/mesh nodes (on every pallet) | B005 Bluetooth Beacon – IP68, 2 × CR2477 (≈ 5 yrs at 0.5 s adv), –20 … +4 dBm, optional AoA & temperature sensor. | Rugged enough for forklifts & shrink-wrapping, IP68 housing ensure zero maintenance even inside shrink-wrap• Large battery supports frequent mesh retransmissions, 5-year life on dual CR2477 (2000 mAh)• AoA upgrade ready if the warehouse later adds gateway-side AoA for zone-level accuracy1 |

| Edge/egress beacon (outside each pallet stack) | Same B005, configured as “mesh-border” node – periodically aggregates IDs from interior beacons and relays them out. | No extra SKU: just a different firmware profile (relay + LoRaWAN uplink scheduler)• 150 m line-of-sight range and adjustable –20 … +4 dBm TX for RF hygiene |

| LoRaWAN + BLE mesh backhaul | SocketSync Bluetooth Gateway (plug-in) for densely racked aisles; Macro Bluetooth Gateway for open, high-bay areas. Both forward BLE data by LoRaWAN and need only mains/battery. | “1 gateway → 1.5 km LoRa” eliminates Ethernet runs• Clock-sync feature lets gateways send a unified epoch that cascades through the mesh, so all beacons TX in the same 30 ms window, reducing RF collisions • AC 85–305 V + 300 mAh backup battery (Socket Sync)• 38 000 mAh Li-SoCl₂, IP66, –45 … +85 °C; > 500 beacons / gateway (Macro)• LoRaWAN OTAA, up to 15 beacon IDs in one SF9 packet |

| Cloud / WMS | Any LNS + application server (e.g. ChirpStack + your ERP/WMS) | Receives pallet ID, last-seen gateway, RSSI & optional temperature; raises “missing pallet” or “wrong-zone” alerts |

Bluetooth Mesh advantage

Interior beacons hop < 0.5 m through dense product, avoiding the 25–30 dB attenuation that defeats direct aisle-mounted receivers. Should the exposed leader get damaged, the next intact node auto-promotes itself, so the pallet never “goes dark”.

Radio Architecture at The Pallet Level

When cartons form a dense 2–3 m cube, direct BLE → gateway links fade to –90 dBm or drop out.

In Bluetooth Mesh, every B005 acts as a relay; the exterior “leader” maintains the friend/relay role.

Mesh PDUs carry the 2-byte company ID + 4-byte pallet UID.

The gateway’s periodic Time Update message synchronises all internal clocks (±100 µs), so relayed bursts appear as one tight packet group, minimising LoRa airtime.

Deployment & Commissioning Workflow for Pallet Tracking

| Step | Action | Tooling |

| 1 | Attach B005s to the pallet-base runner and on every second carton layer (industrial Velcro or cable-tie slot). Scan QR/NFC to bind the UID to the Pallet # in WMS. | Smartphone app |

| 2 | At the marshalling lane, the “leader” beacon is snapped to the outside of the wrap. The app pushes a Leader profile (Relay = ON, Friend = ON, TxPower = 0 dBm). | OTA via BLE |

| 3 | Plug SocketSync gateways into aisle-end sockets; they auto-join LoRaWAN with OTAA and publish their GPS/aisle label. | Web UI |

| 4 | Warehouse map auto-populates pallet icons; pallets that have not reported for > X min are highlighted red. | WMS dashboard |

Implementation Roadmap

1. Tagging – Three B005 Bluetooth beacons Velcroed per pallet (two inside layers, one outside). QR-scan binds beacon UID to pallet ID in the WMS.

2. Gateway drop-in – SocketSync units plug into aisle sockets; Macro units cover high-bay zones where no power exists. All gateways synchronise their clocks via LoRaWAN and broadcast a mesh–time update that aligns every beacon within ±100 µs.

3. Data flow – Interior nodes advertise every 15 s; leader aggregates, compresses, and relays. Gateways forward the list, plus RSSI and optional temperature.

4. Dashboard – WMS flags any pallet not heard for > 5 min; pickers locate it by last-seen gateway and signal strength.

Total rollout: 1800 pallets in three days; 22 gateways for full coverage.

Measured Results (first 12 months)

| KPI | Before | After | Δ |

| Average search time / misplaced pallet | 14 min | 2 min 30 s | –82 % |

| Annual pallet write-offs | €28 000 | €4 000 | –86 % |

| Fork-truck travel | 52 km/day | 38 km/day | –27 % |

| Beacon battery replacements | n/a | 0 (proj. 4.8 yrs) | – |

Why This Architecture Exactly?

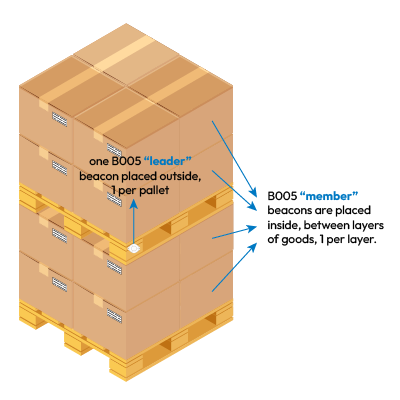

The sketch shows several “member” B005 beacons buried inside the load and one “leader” beacon fixed on the pallet’s outside face. That might sound redundant at first, but it solves three practical problems that a single exterior tag plus a few aisle-mounted relays cannot.

Radio physics: stacked goods absorb a lot of BLE energy

Dense freight (paper, liquids, metalized film) can attenuate 2.4 GHz signals by 25-30 dB.* When a pallet is four-high or wrapped in foil, a tag on the far side can be shadowed from every aisle or ceiling gateway. By letting each inner layer host a low-power “hop”, the packet only needs to travel 0.3–0.5 m through the load before it sees clear air again. The outer “Bluetooth gateway or Bluetooth bridge” then forwards the package. Because the B005’s receiver sensitivity is –96 dBm, even two or three short hops stay comfortably above the noise floor.

Reliability & safety margin

Fork-truck forks, stretch-wrap cutters, or impact with racking can shear off an exposed beacon. If that single tag is lost, the pallet becomes invisible. Keeping one beacon outside (for best RF) and two-plus inside (for redundancy) means the ID still reports even if the leader is damaged; the next intact beacon automatically promotes itself to leader in the mesh.

Clean battery economics

A B005 Bluetooth Beacon runs roughly five years on two CR2477 cells at 0 dBm / 0.5 s advertising. At today’s coin-cell prices, the extra €1–€1.50 of lithium buys multi-year immunity to search-time and write-off costs that average warehouses measure in tens of euros per misplaced pallet.

Why aisle-mounted “relay poles” alone are not enough

| Topic | Only one tag per pallet + aisle relays | One leader (gateway/bridge) + inner mesh nodes (recommended) |

| Coverage inside deep stacks | Relies on a sideways RF path; easily blocked | Guaranteed: short hops escape every layer |

| Asset identity | If the outer tag is torn off, the pallet ID is lost | Any surviving beacon can still advertise its ID |

| Granularity | Row relay sees “something” present; can’t tell which of the 8 pallets is missing | Each pallet keeps its own UID, so WMS pinpoints the exact one |

| Sensor data (temp/shock) | Measures aisle air, not product core | Inner beacons measure conditions that the goods see |

| Install cost | Fewer pallet tags but extra powered relay hardware & wiring | +2–3 beacons per pallet; no extra mains wiring |

Mesh Bandwidth is Not a Bottleneck

A Macro Bluetooth Gateway can ingest up to 15 beacon IDs in a single LoRaWAN packet at SF9. Time-sync from the gateway lets all inner beacons transmit in the same 30 ms window, so the additional traffic from the “buried” nodes costs virtually zero LoRa airtime.

Bottom line

The beacons (~€10 hardware) on a €300+ pallet cut search time by >80 % and slash annual losses by >85 %. Add the ability to log core temperature or shock in transit, and the ROI arrives long before the first battery change.

So, yes—you could try a single outside beacon plus row relays, but in practice, the mixed-media RF shadowing and real-world abuse make the extra inside nodes the simplest, cheapest insurance for always-visible pallets.

Business Impact and Key Takeaways for Customers

With ROI × 6.2 in the first year and a break-even of just seven weeks, the customer now plans to expand the mesh architecture to outbound staging, enabling real-time trailer-load verification and digital proof of custody.

Mesh beats attenuation – stacked water-rich goods (beverages, paper) can attenuate BLE by 25–30 dB. In-pile relays restore a clear RF path without raising Tx power.

Clock-sync = predictable channel usage – synchronised beacons burst in the same time slot, so one LoRaWAN packet carries up to 15 pallet IDs (fits within SF9 duty-cycle limits). Built-in multi-gateway synchronisation prevents packet collisions and lets IT teams add gateways without retuning.

Battery economics – two CR2477s in a B005 (< €3) amortised over five years add < €0.0002 /pallet-day.

Scalable – a single Macro Gateway supports > 500 beacons, so a 10 k-pallet warehouse needs only ~20 gateways spread over LoRa indoor cells.

Rugged & industrial – IP68 beacons survive wash-downs; IP66 Macro Gateways run from –45 °C to +85 °C.

Future-proof – Optional AoA and temperature sensing on the B005 enable sub-metre location or cold-chain monitoring when the business is ready.

“Since installing the Lansitec mesh, we haven’t lost a single pallet. Fork-lift drivers spend less time hunting and more time moving inventory.” — Logistics Manager, 3PL warehouse.

Mini case-study

Background

A 40000 m² 3PL warehouse struggled with misplaced or delayed pallets. Barcode scans were skipped during peak shifts, and Bluetooth tag signals often vanished once pallets were stacked four high.

Solution

Each pallet now carries three Lansitec B005 beacons—two inside the load and one “leader” outside. The beacons form a self-healing Bluetooth Mesh; interior nodes forward their ID to the leader, which broadcasts synchronised advertisements every 15 s.

Strategically placed SocketSync Bluetooth Gateways, Macro Bluetooth Gateways, and Solar Bluetooth Gateways capture the burst and forward a compressed ID list via LoRaWAN to the WMS.

Deployment

A two-person team retrofitted 1800 pallets in three days. No mains wiring was required; gateways simply plugged into existing aisle sockets or ran on 38000 mAh batteries in dead zones.

Results

· Search time for a missing pallet fell from 14 min to < 3 min.

· Annual pallet loss dropped by 86 %.

· Fork-lift travel distance decreased 27 %, saving 18 MWh of electricity in the first year.

· Beacon batteries are projected to last 4.8 years, shrinking maintenance visits to essentially zero.

Business value

Faster order-picking and fewer write-offs translated into a first-year ROI of 6.2 ×, with break-even reached after only 7 weeks.