MetroLink Executive Summary

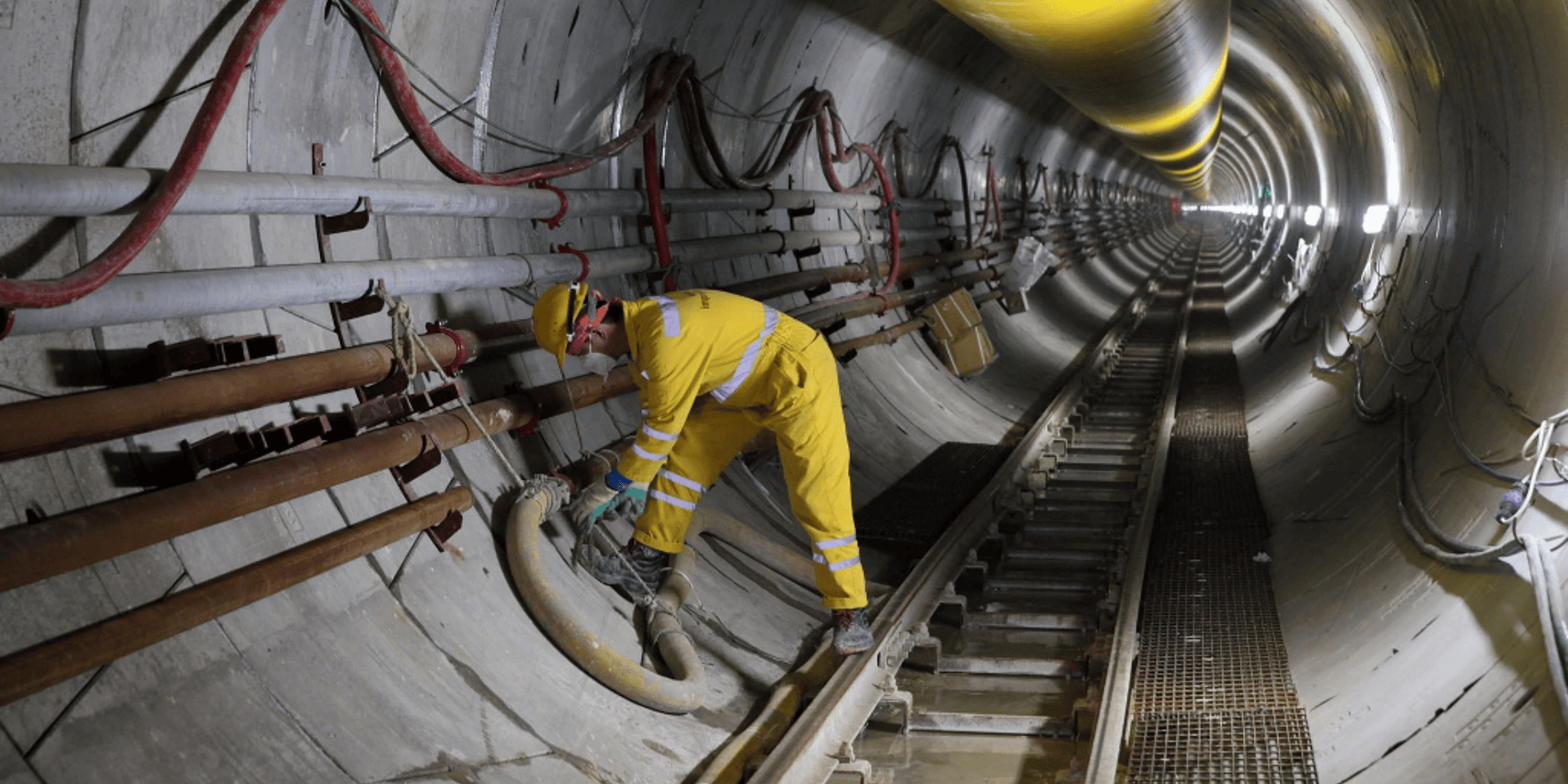

Urban metro systems are the arteries of modern cities, moving millions of people safely and efficiently every day. Yet behind the scenes, thousands of maintenance and operations staff work tirelessly — often underground, often in hazardous conditions — to ensure that this infrastructure stays functional.

Ensuring the safety, accountability, and efficiency of these workers is a growing challenge for transit authorities.

For MetroLink Operations, a mid-sized Australian metro transit operator, this challenge became urgent: with over 400 workers managing more than 75 kilometers of underground tunnels, the company struggled with:

- Limited visibility into worker locations

- Asset loss and equipment tracking issues

- Inefficient emergency evacuations

- Risk of non-compliance with safety regulations

In 2024, MetroLink partnered with Lansitec, a leading provider of Bluetooth-based tracking solutions, to deploy an intelligent real-time location system built around the B011 Helmet Beacon and a network of Bluetooth Angle of Arrival (AoA) gateways. This project has since delivered:

- 95% real-time worker visibility

- 32% faster emergency response times

- 40% reduction in asset losses

- Strong regulatory compliance performance

This case study outlines how MetroLink tackled its underground safety and asset management challenges through smart, scalable technology — and how other metro systems can follow suit.

The MetroLink Operational Challenge

Worker Safety Gaps

Without a real-time system to track individual workers underground, it was difficult to know:

- Who was on site at any given time

- Whether all personnel had exited after a shift or emergency

- How to quickly locate an injured or unresponsive team member

Asset Accountability

MetroLink’s maintenance teams used valuable, portable equipment daily: pressure testers, oxygen meters, mobile generators, drills, and battery units.

But with no real-time tracking, equipment was often:

- Left behind in hard-to-reach locations

- Moved between teams without documentation

- Lost entirely, triggering unnecessary replacements

Emergency Evacuation Inefficiency

Although MetroLink conducted regular evacuation drills, their reliance on paper logs and radio check-ins left them vulnerable:

- Muster times were inconsistent and slow

- Incident response coordination was reactive, not proactive

- Post-incident reporting lacked audit-ready clarity

Compliance Pressures

Australian safety regulations require infrastructure operators to demonstrate:

- Real-time accountability for underground workers

- Documented safety drills and evacuation performance

- Reliable emergency notification systems

MetroLink knew their existing systems — a combination of radio communication, manual logs, and CCTV coverage — would not stand up to scrutiny in a serious incident. They needed a smarter, integrated, and non-intrusive solution.

The Solution: Lansitec’s Smart Beacon Ecosystem

In mid-2024, MetroLink initiated a competitive evaluation of real-time location systems (RTLS), ultimately selecting Lansitec’s B011 Helmet Beacon platform. The choice was driven by several key factors:

Why Lansitec?

- Bluetooth AoA for Underground Environments – Lansitec’s solution uses Bluetooth 5.1 with Angle of Arrival (AoA) technology, which triangulates the position of beacons worn by workers with impressive accuracy — even in long, curved tunnels.

- Seamless Helmet Integration – The B011 is lightweight (just 90g), rugged (IP66-rated), and designed to attach to standard hard hats without interfering with safety compliance or comfort.

- Long Battery Life – With a 1200mAh rechargeable battery, the B011 can operate for up to one full year on a single charge — reducing the need for frequent maintenance.

- Emergency-Ready Features – The beacon offers optional buzzer alerts, customizable advertise intervals, and can integrate with fall-detection and SOS systems — all essential in emergency response scenarios.

- Full Ecosystem Support – Lansitec also supplied:

- Macro Bluetooth Gateways (for tunnels and service zones)

- Indoor Gateways (for depots and control rooms)

- Solar Gateways (for above-ground entry/exit areas)

- LoRaWAN backhaul (for long-range data transmission without heavy network infrastructure)

Deployment Overview

The project was rolled out in two major phases:

Phase 1: Pilot Trial

MetroLink launched a pilot in its Central Loop — a high-traffic 12-km tunnel section.

- 50 workers were equipped with Helmet Beacons.

- Bluetooth AoA gateways were installed every 80 meters.

- A centralized dashboard was tested for real-time worker location tracking.

The pilot demonstrated:

- Accurate indoor positioning (within 3 meters)

- Quick evacuation time improvements during drills

- Positive user feedback from staff and supervisors

Phase 2: Full Network Rollout

- 400 Helmet Beacons issued to all underground staff

- 325 Macro Gateways installed in tunnels and switching areas

- 30 Solar Gateways deployed above ground

- LoRaWAN integration linked the system to MetroLink’s central control center

- Automatic reporting tools configured for compliance tracking and audits

Business Results

After just six months, MetroLink began to see measurable operational benefits:

Safer Workers

- Real-time monitoring increased underground situational awareness.

- Evacuation drill times dropped by 28%.

- Workers expressed greater peace of mind, citing the ability to call for help and be located immediately.

Fewer Lost Assets

- Equipment tracking reduced misplacement rates by 40%.

- Fewer delays due to unavailable or missing tools.

- Over AU$120,000 in avoided equipment losses projected annually.

Faster Response Times

- Incidents requiring medical or supervisory attention saw response times drop by 32%.

- Control room staff could instantly identify and guide the closest available responders.

Stronger Compliance

- MetroLink passed two back-to-back audits with no violations.

- Evacuation records, location data, and alert logs were available on demand.

- Regulators praised the company’s “proactive approach to underground personnel safety.”

Improved ROI

- The total system investment achieved ROI within 18 months.

- Projected annual savings of AU$280,000 across safety, efficiency, and insurance categories.

Worker-Centered Design and Adoption

Crucially, the B011’s ease of use helped ensure smooth adoption:

- No complex onboarding — devices clipped on in seconds

- Maintenance-free: no daily charging

- No behavior change needed from workers

This frictionless design led to over 95% daily usage compliance, even months after deployment.

Conclusion: A Safer, Smarter Metro Network

By choosing Lansitec’s B011 Helmet Beacon system and supporting Bluetooth AoA infrastructure, MetroLink turned a growing safety and operational challenge into a powerful opportunity to modernize its entire underground workforce management model.

Today, MetroLink can:

- See every worker, every shift, in real time

- Account for every person during emergencies

- Instantly locate any critical tool or asset

- Prove compliance through data-backed reporting

This isn’t just a technological upgrade — it’s a cultural shift toward transparency, accountability, and safety-first operations.

What’s Next?

As MetroLink’s digital transformation journey continues, the company is preparing for:

- Contractor tracking (temporary beacon issuance)

- Station personnel visibility (crowd management and security response)

- Predictive maintenance integration (using temperature and movement sensors on critical equipment)

Continue to Part 2: The Technical Deployment Deep Dive →

In the next section, we’ll break down the system architecture, AoA gateway placement strategy, beacon data flows, and key lessons learned during implementation.